Revolutionary heavy weightlifting: Specific spherical head lifting anchor

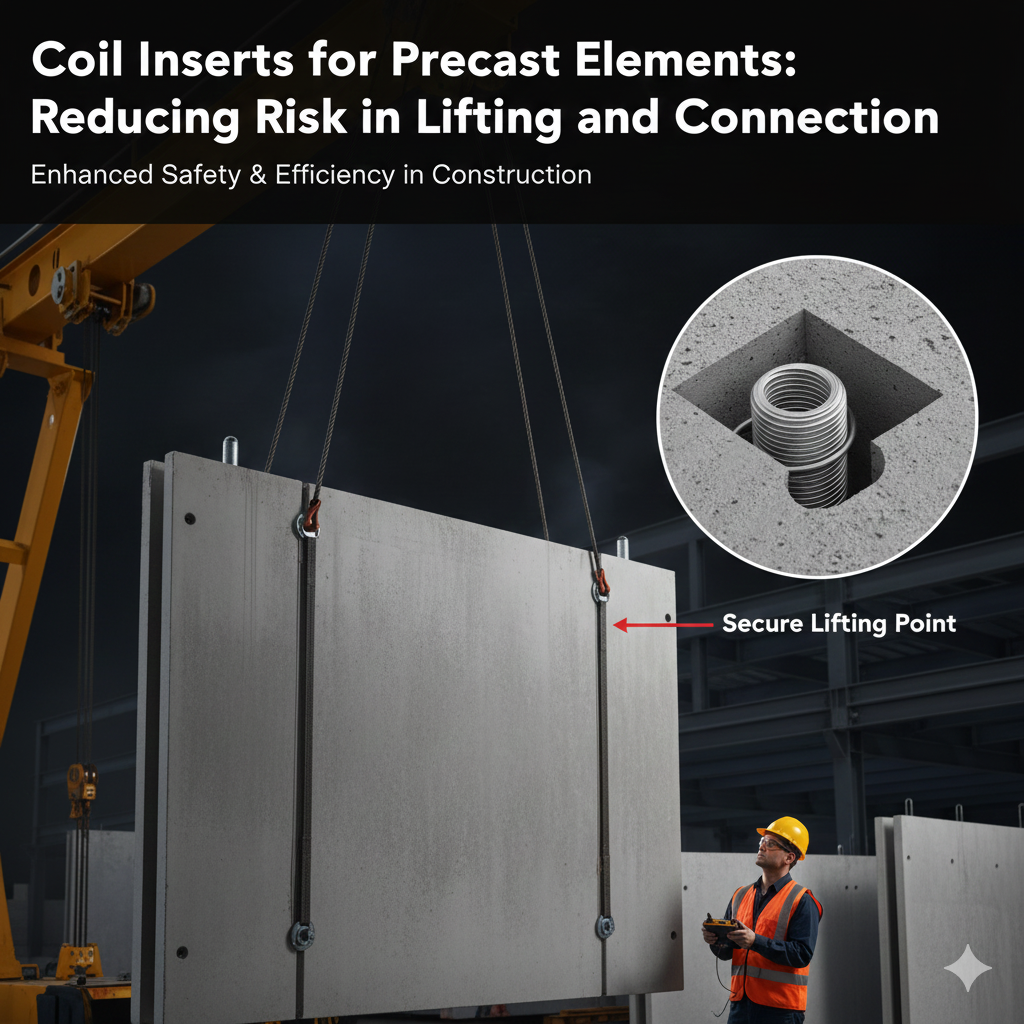

Efficiency, safety and accuracy are crucial in construction and precast concrete projects, where the concrete spherical lift anchor can be delivered by these three. This innovative tool brings unparalleled reliability and cutting-edge technology to the forefront. Paired with a powerful lift clutch system ensures maximum performance and safety during lift operation.

Excellent features and benefits

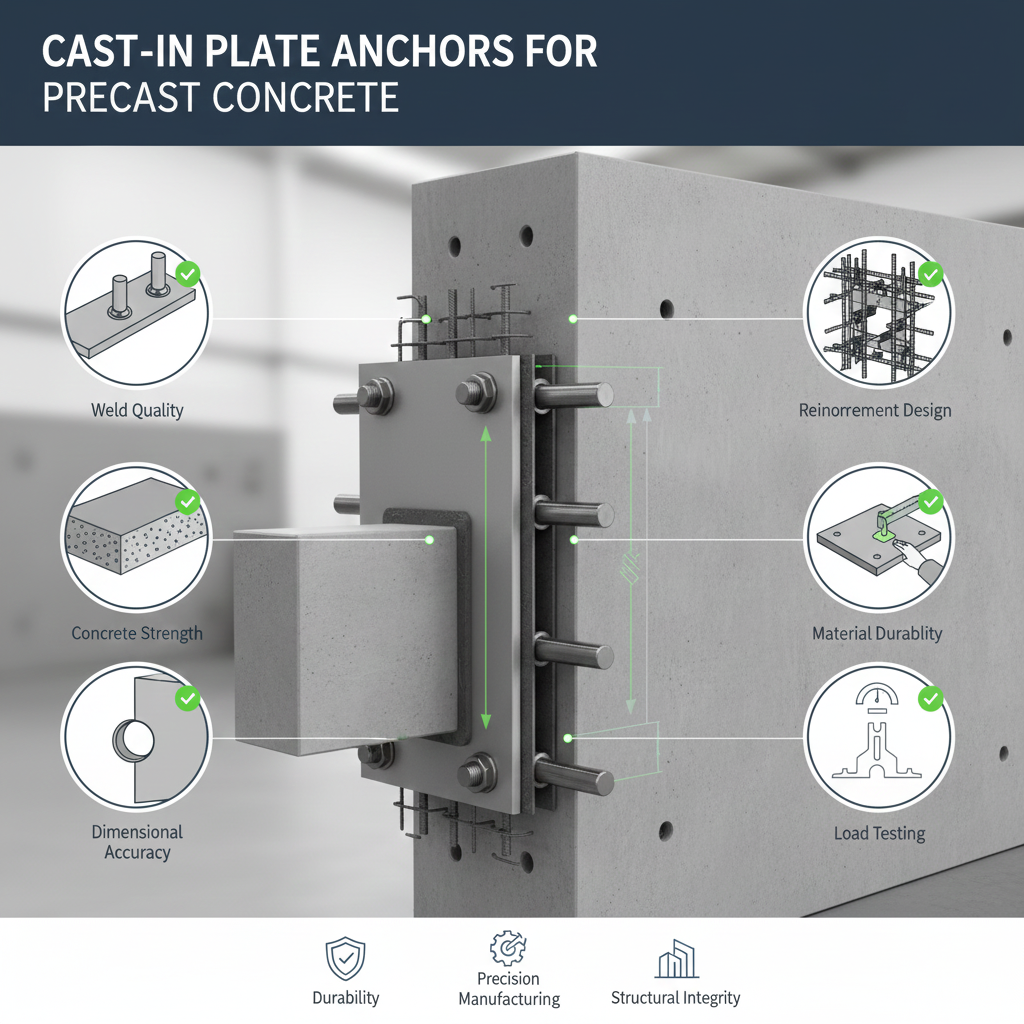

The concrete spherical lift anchor type is designed to withstand the challenges of heavy lifting and is supported by advanced steel construction to provide excellent durability and load capacity. Its spherical head system is carefully designed to reduce stress concentrations and enhance safe interactions, making each lift smoother and safer. Combined with the lifting clutch mechanism, the anchor promotes a worry-free adhesion and disengagement process, which greatly reduces operating time.

The corrosion-resistant finish makes the anchor perfect for use in extreme weather conditions, ensuring it remains reliable even in much-needed needs. The slender pin design improves versatility and can accommodate a variety of concrete element sizes without any compromises. This fusion of strength and adaptability separates the anchors, marking them as tools that can be trusted in almost all cases.

Style is in line with practicality

In addition to its significant function, the concrete spherical lift anchor is ergonomic. Streamlined frames and geometric aesthetics reflect a modern industrial atmosphere and function. It is rare to see a tool that not only performs well, but also exudes a visual appeal that fits into professional-grade built environments.

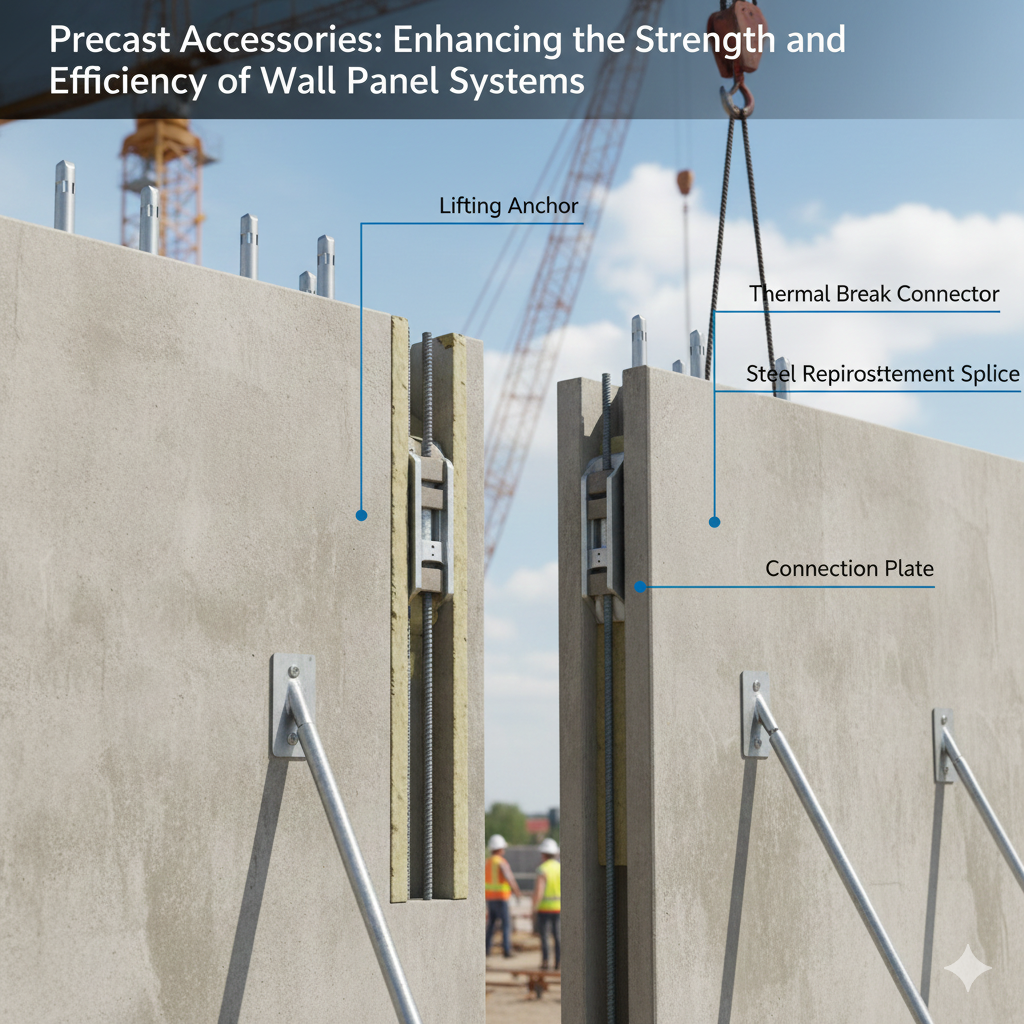

Whether it is lifting up a massive concrete panel or handling prefabricated blocks with precise accuracy, anchoring is built to perform well when it matters most. Its stylish and powerful design improves ease of use while promoting operational efficiency of construction and infrastructure projects.

Application of modern industry

From large-scale construction sites to prefabricated manufacturing plants, the spherical head lifting anchor of concrete will be seamlessly integrated into your workflow. It is specially designed to handle demanding tasks such as moving heavy panels, lifting prefabricated blocks, and even managing complex infrastructure components. Its compatibility with ball lift clutch enhances its adaptability and positions it as a must-have for any professional looking to achieve perfect execution.

Why choose concrete spherical lift anchor?

Obsolete weightlifting mechanisms can hinder progress and lower the edge of safety, but the anchor represents the pinnacle of advanced engineering and innovation. By combining cutting-edge technology with durable materials, it ensures that each lift is performed with the highest accuracy and safety. Whether you're looking for security, first-class reliability or modern design, this anchor ticks all boxes.

Enter the future of heavy lifting through concrete spherical head lifting anchors. This is not only a tool, but a partner to take your project to new levels of efficiency and excellence. Let this groundbreaking product set a new benchmark in the world of heavy-duty structures and precast concrete treatments.