Challenge of Heavy Duty Precast Concrete Elements

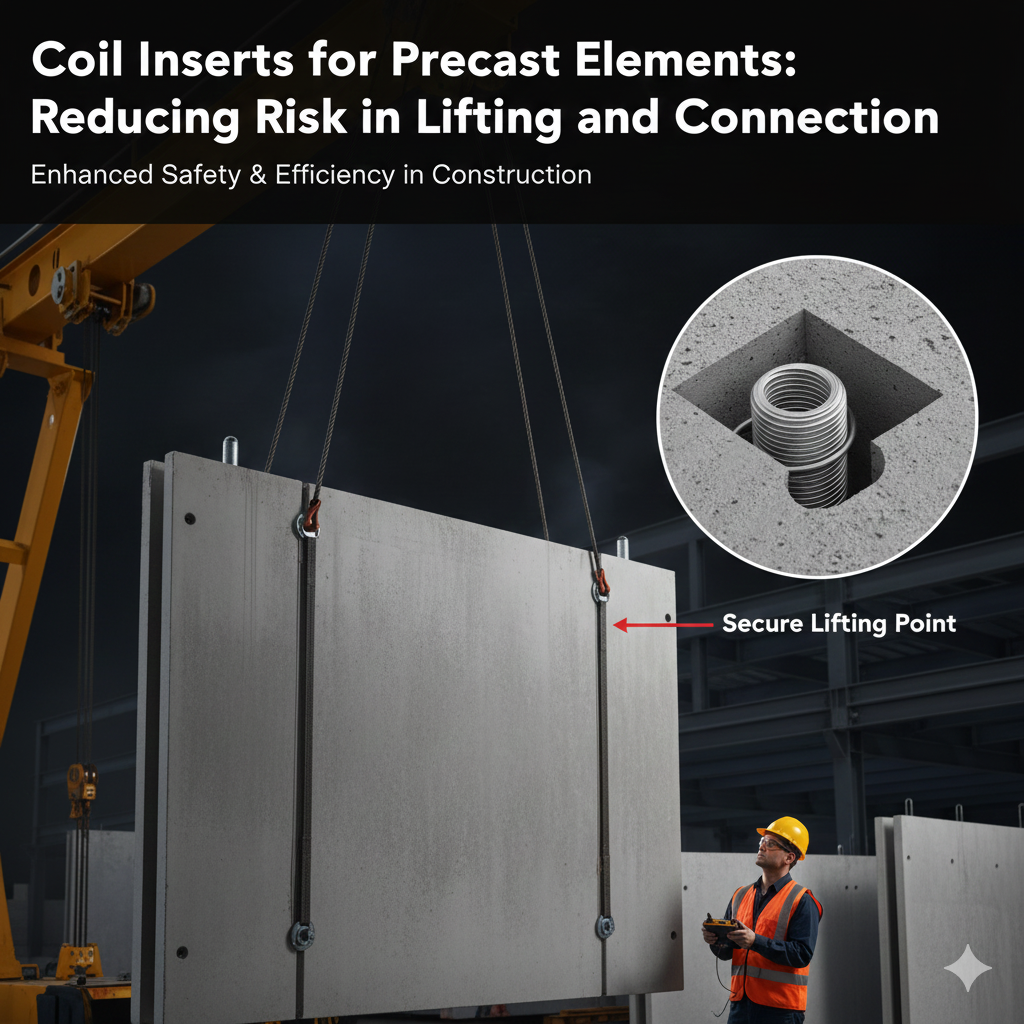

Effective and safe handling of heavy concrete blocks has always posed a major challenge in the construction and logistics industry. Typically, traditional lifting methods lead to an increased risk of accidents, delays and damage to concrete elements and lifting equipment. For many professionals, finding a reliable, durable and easy to use solution seems elusive. This need for better approaches drives innovation toward creating tools and systems designed specifically to address these challenges.

The importance of a powerful lifting solution

Input the innovative ** concrete lift anchor system**, a cutting-edge solution designed to revolutionize the lifting and fixation of precast concrete elements. The system uses components such as the **weight clutch, which simplifies the lifting process while ensuring maximum safety and efficiency. At the heart is powerful hardware designed to meet the most demanding industry standards.

Combined with impeccable engineering and practical design, the unique red weight lifting hook is crucial to the system. Their vibrant colors not only add visual appeal, but also serve as a safety feature to ensure they are easily recognizable in the workplace. These hooks are seamlessly connected to the top metal lifted eyes** and they fit perfectly into the molded dents of concrete blocks. The raised eyes are made of high-strength material that distributes the weight evenly, avoiding potential pressure or damage during lifting. Strategically designed anchor points ensure a safe connection between lifting components, eliminating the risk of failure during operation.

Why choose a concrete lifting anchor system?

The benefits of this product are clear and comprehensive. First, the upper lift clutch for lifting anchors is designed to be easy to use. Its fast locking and release mechanism reduces downtime, making operation faster and more efficient. This feature not only ensures smooth workflow, but also helps workplace safety by minimizing manual intervention.

In addition, the system's sleek, ergonomic design blends style and function, providing a modern twist to traditional lifting tools. From rugged hardware to seamless compatibility with precast concrete blocks, it was built to redefine industry standards and enhance project outcomes. The system isn't just a mention; it's an investment in durability, reliability and cutting-edge performance.

Whether you are involved in a large construction project or need to handle the logistical tasks that precisely deal with heavy elements, this lifting anchor solution is the final answer you ask for. By prioritizing safety, simplifying operations, and providing unparalleled durability, it promises to increase your productivity and redefine your workplace efficiency.