Stainless Steel CNC Turning Parts: Controlling Heat, Wear, and Consistency

Stainless steel does not forgive rushed machining.

It resists cutting, holds heat, and remembers every poor decision made along the way.

For CNC turning operations, this means one thing: parts that look acceptable at low volume can become unstable as production scales. Diameter drift, surface tearing, and accelerated tool wear are not random problems. They are predictable outcomes of how stainless steel reacts under sustained cutting conditions.

Why Stainless Steel Behaves Differently on the Lathe

Compared with aluminum or mild steel, stainless steel work-hardens aggressively. Each pass that generates excessive heat makes the next pass more difficult.

This behavior turns CNC turning into a thermal management problem, not just a geometric one.

If heat is allowed to accumulate, several things happen at once:

-

cutting forces rise

-

surface finish degrades

-

tool life shortens

-

dimensional stability erodes

Once this cycle begins, correction becomes expensive.

Material Grade Sets the Machining Strategy

“Stainless steel” covers a wide range of alloys, each with distinct turning behavior.

| Stainless grade | Practical machining implication |

|---|---|

| 303 | Easier chip control, better finish |

| 304 | Balanced corrosion resistance, higher work hardening |

| 316 | Tougher cutting, greater heat retention |

| 420 / 440 | Higher hardness, increased tool wear |

A reliable CNC turning process starts by matching cutting strategy to grade behavior, not by applying one universal parameter set.

Chip Control Is a Primary Quality Driver

In stainless steel CNC turning parts, uncontrolled chips cause more than cosmetic issues. Long, stringy chips trap heat near the cutting edge and damage finished surfaces.

Effective chip breaking improves:

-

heat dissipation

-

surface consistency

-

tool life stability

Suppliers that treat chip control as secondary often see rising variation as production continues.

Tool Selection and Wear Monitoring Matter More Than Speed

Tooling choices directly affect repeatability.

Coatings, edge preparation, and insert geometry determine how heat and friction are managed at the cutting interface. Running tools too aggressively may increase short-term output but usually leads to premature wear and dimensional drift.

| Tooling factor | Impact on turned parts |

|---|---|

| Insert geometry | Controls cutting force |

| Coating type | Manages heat and friction |

| Wear monitoring | Prevents gradual drift |

| Tool change discipline | Maintains consistency |

In stable operations, tool wear is anticipated—not discovered after parts fail inspection.

Fixturing and Bar Control Affect Roundness and Concentricity

CNC turning accuracy depends heavily on how material is supported.

Poor bar straightness, inconsistent chuck pressure, or inadequate tailstock support introduce subtle errors that compound over time. These issues often remain invisible in short runs but become critical in longer batches.

Controlling these variables is essential for maintaining concentricity and repeatability.

Surface Finish Is Functional, Not Decorative

In stainless steel CNC turning parts, surface condition influences:

-

sealing performance

-

fatigue behavior

-

corrosion resistance

Surface tearing or micro-burnishing often signals excess heat or tool wear. Addressing finish issues requires correcting the process—not polishing the result.

Inspection Must Reflect Stainless Steel Behavior

Final inspection alone often hides emerging problems. Stainless steel parts may pass measurement immediately after turning, then drift as residual heat dissipates.

| Inspection approach | Value |

|---|---|

| In-process measurement | Detects thermal drift |

| SPC tracking | Identifies gradual variation |

| Surface roughness checks | Confirms process health |

| Diameter trend analysis | Predicts tool wear impact |

Inspection aligned with process behavior prevents late-stage surprises.

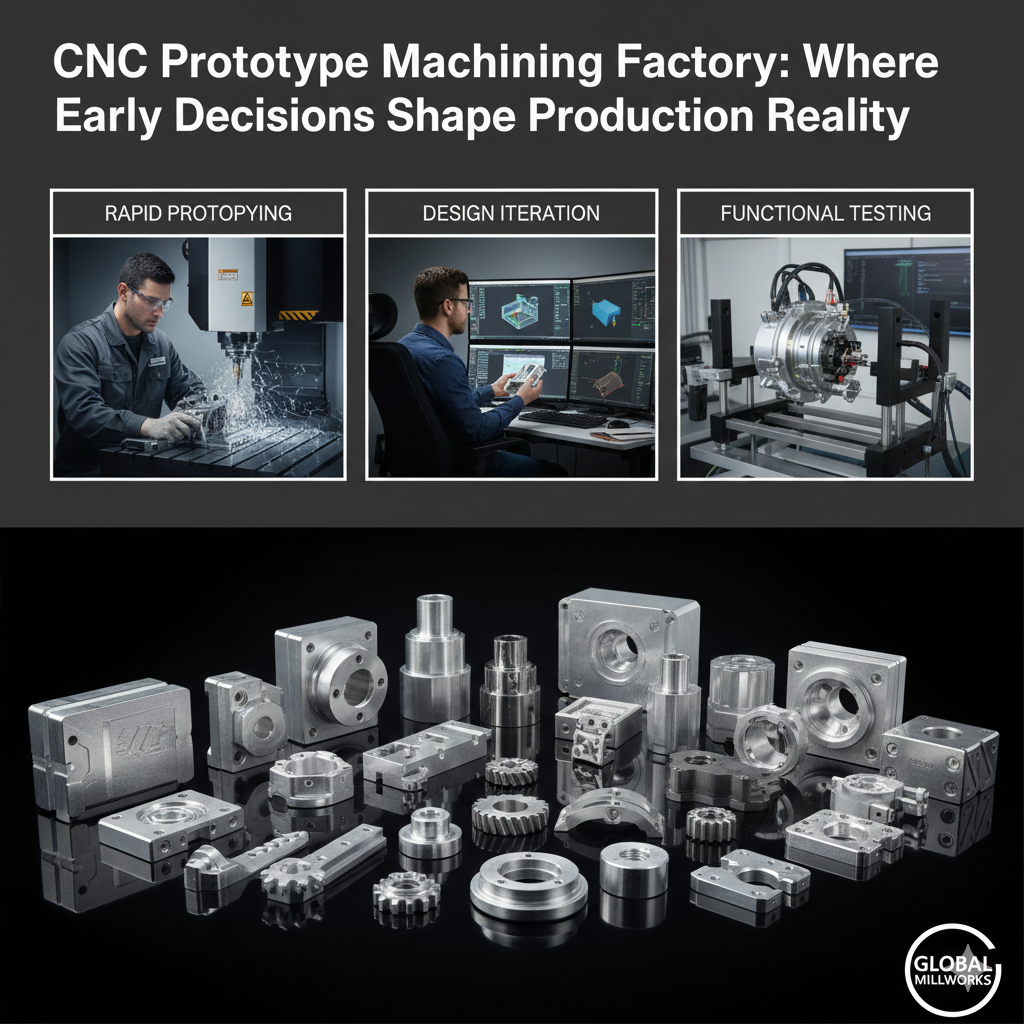

Scaling Stainless Steel Turning from Sample to Production

Prototype success proves feasibility.

Production stability proves capability.

As batch size increases, tool wear, heat buildup, and operator variation expose weaknesses in turning strategy. Suppliers prepared for scale design processes that tolerate these variables without losing control.

Manufacturers such as Jingle approach stainless steel CNC turning with long-run stability as a baseline requirement, not an optional upgrade, ensuring consistent output across extended production schedules.

Where Stainless Steel CNC Turning Parts Are Most Critical

Stainless steel turned components are used where failure is not an option:

| Application | Typical part role |

|---|---|

| Construction hardware | Load-bearing connectors |

| Industrial equipment | Shafts and bushings |

| Energy systems | Couplings and fittings |

| Fluid handling | Valves and sleeves |

| Automation | Precision rotating elements |

Across all applications, reliability depends on managing heat, wear, and repeatability—not just meeting initial dimensions.

Cost Pressure Usually Appears Late

In stainless steel turning, cost issues rarely stem from machine time.

They surface as:

-

accelerated tool consumption

-

rising scrap rates

-

inspection escalation

-

delayed deliveries

Stable processes minimize these hidden costs, even if cycle times appear conservative.

Stainless Steel Rewards Discipline

Stainless steel CNC turning parts demand respect for material behavior. When heat, tool wear, and inspection strategy are aligned, stainless steel delivers exceptional durability and consistency.

When they are not, problems emerge slowly—and expensively.

To explore stainless steel CNC turning capabilities and related industrial components, visit the Jingle home page or reach out via the contact page for project-specific technical discussions and documentation support.