Aluminum CNC Precision Parts: Managing Accuracy, Stability, and Production Risk

Aluminum is often described as easy to machine.

In practice, it is easy to cut—but not always easy to control.

Many aluminum CNC parts look correct when they leave the machine. Problems tend to surface later: during inspection, during assembly, or after parts sit for a short time and dimensions drift. These issues are rarely caused by programming mistakes. They are the result of material behavior interacting with process decisions.

Why Aluminum CNC Parts Behave Differently

Compared with steels, aluminum alloys respond more sensitively to machining stress and temperature variation. Material removal releases internal stress quickly, and thin sections react immediately.

This means that dimensional accuracy in aluminum CNC precision parts depends less on how tight a tolerance is specified, and more on how that tolerance is protected throughout the process.

Ignoring this distinction leads to parts that pass measurement but fail fit.

Material Condition Sets the Baseline

Not all aluminum behaves the same, even within the same alloy family.

Temper condition, residual stress from rolling or extrusion, and batch variation all influence machining outcomes.

| Material factor | Practical impact |

|---|---|

| Alloy series (6061, 7075, etc.) | Strength vs machinability trade-offs |

| Temper condition | Affects stress release |

| Internal stress level | Drives post-machining distortion |

| Batch consistency | Influences repeatability |

Experienced CNC teams evaluate aluminum stock condition before deciding machining order or clamping strategy, rather than assuming uniform behavior.

Thin Walls and Flatness Are Where Risk Accumulates

Aluminum precision parts frequently include thin walls, pockets, and large flat surfaces. These features amplify distortion risk.

Removing material unevenly causes parts to move once clamping force is released. The part may remain within tolerance initially, then shift hours later.

Effective strategies focus on balanced material removal, intermediate stress relief when necessary, and controlled sequencing rather than aggressive cycle time reduction.

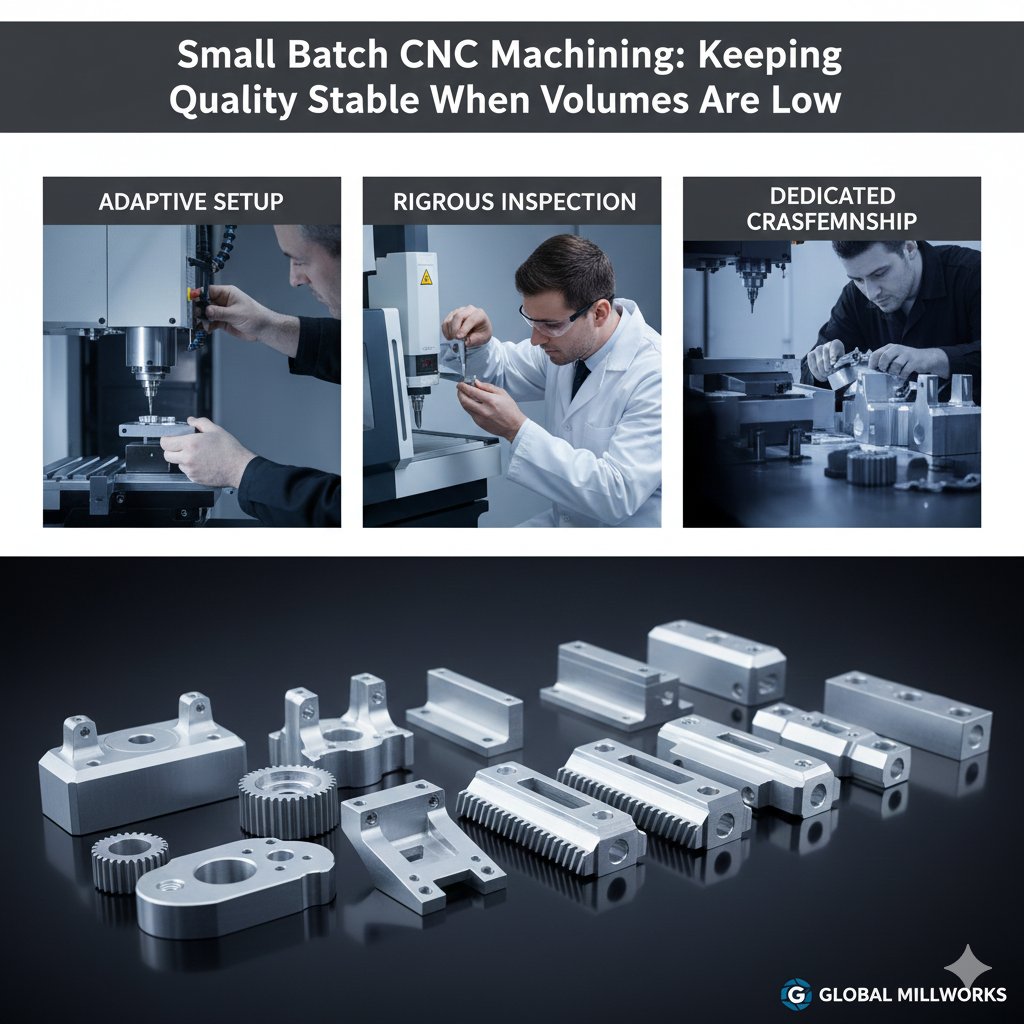

Fixturing Determines Repeatability More Than Speed

Fixturing is often underestimated in aluminum machining because cutting forces are relatively low.

That assumption creates variation.

Aluminum parts deform more easily under clamping pressure. Excessive force improves rigidity during cutting but compromises geometry after release.

| Fixturing consideration | Effect on aluminum parts |

|---|---|

| Clamping force distribution | Controls deformation |

| Datum selection | Preserves functional geometry |

| Fixture repeatability | Maintains batch consistency |

| Setup verification | Reduces operator-induced variation |

Suppliers who tune fixturing specifically for aluminum achieve far more stable results than those using generic setups.

Surface Finish Is a Functional Variable

In aluminum CNC precision parts, surface finish is rarely cosmetic.

It affects sealing performance, sliding behavior, coating adhesion, and fatigue life.

Tool condition, cutting parameters, and coolant strategy all influence surface integrity. Inconsistent finishes often signal deeper process instability rather than isolated tool issues.

Inspection Strategy Must Match Aluminum Behavior

Final inspection alone is often insufficient for aluminum parts.

Distortion may occur after inspection, especially when parts are removed from fixtures or stored.

| Inspection approach | Value for aluminum CNC parts |

|---|---|

| In-process measurement | Detects movement early |

| Time-delayed inspection | Reveals post-machining drift |

| SPC trend tracking | Identifies gradual variation |

| Flatness and parallelism checks | Confirms functional geometry |

Inspection aligned with material behavior reduces late-stage surprises.

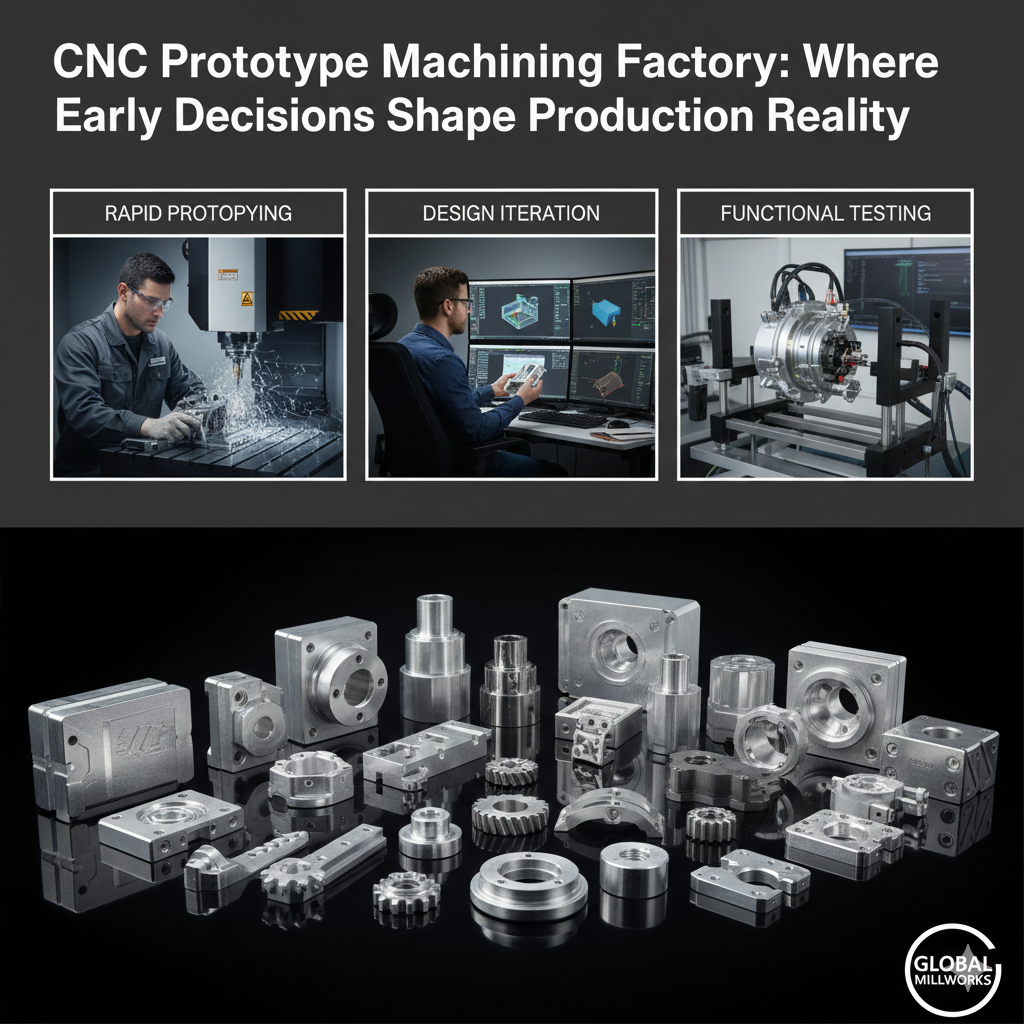

Scaling Aluminum CNC Parts from Prototype to Production

Prototype success does not guarantee production stability.

As quantities increase, tool wear, temperature variation, and fixture fatigue expose weaknesses in process control.

The suppliers who scale successfully treat aluminum machining as a system, not a sequence of cuts.

Manufacturers such as Jingle focus on controlling material input, fixturing repeatability, and process feedback to maintain dimensional stability across long production runs.

Where Aluminum CNC Precision Parts Deliver the Most Value

Aluminum CNC parts are widely used where weight, corrosion resistance, and machinability matter:

| Application | Typical role |

|---|---|

| Construction hardware | Structural brackets |

| Industrial equipment | Frames and mounts |

| Energy systems | Interface components |

| Automation | Alignment-critical parts |

| Transportation | Lightweight structural elements |

Across all applications, reliability depends on controlling how aluminum behaves—not just how it is machined.

Cost Appears Later Than Expected

In aluminum CNC machining, cost overruns rarely come from cutting time.

They come from scrap, rework, delayed assembly, and inspection escalation.

Stable processes reduce these downstream costs, even if initial machining appears slower or more conservative.

Aluminum Rewards Control, Not Aggression

Aluminum CNC precision parts succeed when material behavior, fixturing, and inspection are aligned from the start. Suppliers who respect aluminum’s sensitivity deliver parts that remain accurate beyond the machine—through assembly, storage, and service.

Those who treat aluminum as “easy” often learn otherwise later.

To explore aluminum CNC machining capabilities and related industrial components, visit the Jingle home page or reach out via the contact page for project-specific technical discussions.